CeFEMA’s activities are developed in the following research Laboratories.

Electron Microscopy Facility

Electron Microscopy – MicroLab

Deputy Director

Maria Amélia Almeida

Contact Persons

Maria Amélia Almeida, ext. 3176

Isabel Nogueira, ext. 1882

Description

MicroLab is the Electron Microscopy Facility of IST dedicated to provide service and training in materials characterization by scanning and transmission electron microscopy to the entire community. CeFEMA is a member of the facility.

MicroLab is the MERIL infrastructure 3502 (MERIL-Mapping of the European Research Infrastructure Landscape) database since August 2013. MERIL provides access to an inventory of the most excellent research infrastructures (RIs) in Europe across all scientific domains, considered of more-than-national relevance. According to this platform’s requirements, research infrastructures included in the database have been evaluated through a national or European process on the basis of commonly agreed criteria and recognized as being of the highest standards and relevance to research in Europe. Inclusion in the database is a label of quality.

Objectives

MicroLab is a specialised facility of IST dedicated to provide service and training in materials characterization by scanning and transmission electron microscopy to the entire community.

Activities

The laboratory performs structural and chemical analysis of a wide range of materials and biological samples using secondary electrons and backscattered electrons imaging scanning electron microscopy, elemental analysis including EDS X-ray mapping, crystallographic and texture analysis by electron-backscatter diffraction, particle sizing and counting, image analysis and specialized sample preparation. In transmission electron microscopy bright-field and dark-field imaging, phase identification by electron diffraction, elemental analysis with EDS and specialized sample preparation can be done.

— Main Scientific Areas

This laboratory provides support for a wide range of scientific research activities, including bulk materials and thin film characterization, nanoparticles analysis, studies of laser processed materials, etc. In the biological field studies malaria-affected cells, bacteria research, characterization of biomaterials, study of laser ablated human and animal hard-tissues, tissue engineering, magnetic materials for biomedical applications, and calcified structures within the oral cavity are being investigated.

— Training Activities

MicroLab organises personalized training sessions for intensive users who wish to become independent operators of specific equipment.

Training includes a theoretical component and practical sessions, with the support of the laboratory technician. If the training is successful the laboratory technician will authorise the user to have operate the equipment by himself and to access the laboratory off working hours at a reduced cost. In addition, MicroLab support teaching and training within the framework of the University curricular activities. SEM and TEM courses are provided to the Materials Engineering BSc, MSc and PhD degree students as well as to the Biomedical Engineering and Bioengineering and Nanosystems Engineering MSc students. We also receive regular visits from BSc and MSc degree students of Faculdade de Ciências da Universidade de Lisboa and Faculdade de Ciências e Tecnologia da Universidade Nova de Lisboa. The laboratory regularly organizes training courses for those interested in learning more about microscopy, including practical equipment operation training.

Main Equipment

— Hitachi H-8100, 200 kV, LaB6 filament, analytical transmission electron microscope with ThermoNoran model SystemSix energy dispersive X-ray spectrometer (EDS) with light elements detector and digital image acquisition

— JEOL 7001F analytical FEG-SEM, with Oxford INCA 250 PREMIUM EBSD (electron backscatter diffraction) and energy dispersive X-ray spectrometer (EDS) with light elements detector

— Hitachi S-2400 analytical SEM, with a Bruker Quantax energy dispersive X-ray spectrometer (EDS) and light elements detector

— Technoorg Linda IV7 Pro Ion Mill for transmission electron microscopy thin foil preparation

— Dimpler VCR D500i for transmission electron microscopy thin foil preparation

— Technoorg-Linda electroerosion unit for transmission electron microscopy thin foil cutting

— Polaron Quorum Technologies sputter coater and evaporator (Au/Pd, Cr, C films)

— Olympus optical microscope

— Nikon binocular microscope

Further information is available in https://microlab.tecnico.ulisboa.pt.

Location

IST-Alameda, Pav. Mecânica II, room 1.40a

Access conditions

MicroLab is available for all undergraduates, graduates, professors and researchers of CeFEMA as well as from other departments of Instituto Superior Tecnico, other universities, research institutes and private companies. The Facility is available both as user-run for authorized independent users and as a service with technical assistance. This Facility has a full-time technician, responsible for the operation of all equipment, maintenance, online booking and support to independent users.

Intensive users of the Facility are encouraged to become independent operators, being authorized to use the equipment in off-peak hours (before 9h00, after 17h00 and on weekends and holidays) after appropriate training by the responsible technician.

Independent authorized users: please use the online booking system available.

Other users: please contact Isabel Nogueira.

Scanning Probe Microscopy

Contact person

Alberto Ferro, ext 9989

Equipment

— Scanning probe microscope NanoSurf Easyscan 2 (tip-scanning type) with controlled temperature liquid cell and electrochemical cell

— Inverted optical microscope: Inverted Epi and Diascopic Optical Microscope Olympus IX5

Location

IST-Alameda, Mecânica II building, floor 0, NanoStructured Materials Laboratory

Access conditions

Through the contact person above.

Analytical FEG-SEM, JEOL 7001F with Oxford INCA light elements EDS detector and EBSD detector.

Analytical SEM, Hitachi S2400 with Bruker light elements EDS detector.

Analytical TEM, Hitachi 8100 with ThermoNoran light elements EDS detector and digital image acquisition.

Polaron Quorum Technologies sputter coater and evaporator (Au/Pd, Cr, C films).

Technoorg Linda IV7 Pro ion mill.

Atomic force microscope.

Soft Matter Laboratory

Nuclear Magnetic Resonance – NMR Lab

Responsible

NMR Relaxometry, Pedro Sebastião, ext. 3210

NMR Spectroscopy, João Figueirinhas, ext. 3359

Description

The NMR Lab is specially prepared for studies of spectroscopy and relaxometry of complex fluids. Liquid crystals, ionic liquids, polymers, dendrimers, and other complex systems are examples of systems usually studied in this laboratory.

The laboratory is integrated in the Portuguese Nuclear Magnetic Resonance Network.

Main equipment

— Conventional solid-state NMR spectrometer, Bruker Avance II 300, Avance II Console (6 MHz – 365MHz)

— KEA2, 5-100 MHz Magritek NMR console

— Bruker Widebore, Ultra-shielded 7.1 Tesla Superconducting Magnet

— Bruker BE-30, 0-2.4 Tesla Electromagnet (used with Bruker Avance II Console)

— Fast Field Cycling NMR spectrometer for proton relaxation measurements in the Larmor frequency range of 5kHz – 9 MHz.

Location

IST-Alameda, Complexo Interdisciplinar, floor -2

Access conditions

Within collaborative research work. Contact the scientific researcher in charge.

Electro-optical characterization

Responsible and contacts

João Figueirinhas, ext. 3359

Description

Electro-optical cells containing LC in different conditions of confinement in a variety of matrices (e.g. PDLC systems of different types, cellulosic films, ...) are studied in this lab. Besides the investigation of fundamental physical properties of these systems (e.g. refractive indices and visco-elastic parameters) most of the undertaken research have in mind the development and optimization of devices with potential technological applications: LC displays, electrically driven shutters, light valves.

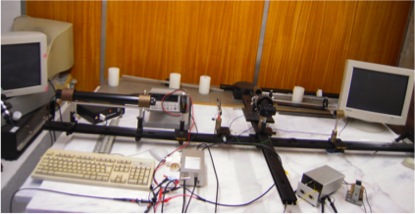

The electro-optical setup is composed of an optical bench equipped with a He-Ne laser and computer controlled systems associated with a function generator, voltage amplifier, digital scope, light detectors and temperature variation of sample cells.

Location

IST-Alameda, Complexo Interdisciplinar, floor -2

Access conditions

Within collaborative research work. Contact the scientific researcher in charge.

X-Ray Diffractometry and Polarized Optical Microscopy

Responsible

Carlos Cruz

Contact persons

Carlos Cruz, ext. 3209

João Figueirinhas, ext. 3359

Description

This laboratory includes basic facilities for sample preparation, polarising optical microscopy observations and X-Ray diffractometry of powder samples. The X-ray diffractometer is equipped with an INEL gas curved counter and a temperature control system particularly useful for the study of phase transitions and structural characterization of liquid crystals.

Location

IST-Alameda, Complexo Interdisciplinar, floor -2.

Access conditions

Within collaborative research work. Contact the scientific researcher in charge.

Conventional 300MHz solid state NMR spectrometer.

Polarising Optical Microscope – Identification of Liquid Crystal Phases.

Fast Field Cycling NMR spectrometer for proton relaxation measurements in a very wide magnetic field range (10-4 T – 0.2 T).

Electro-optical characterization – Development and measurement of physical properties of novel liquid crystal cells for LC displays (LCD technology).

X-ray diffractometer.

Polarising Optical Microscope – Identification of Liquid Crystal Phases.

Thin Films Deposition and Characterization Laboratory

Low Dimensional Semiconductors – LDS

Responsible

Reinhard Schwarz

Contact persons

Reinhard Schwarz, ext. 3952

Rachid Ayouchi, ext. 3775

Description

Deposition and opto-electronic characterization of semiconducting, insulating, and ferroelectric thin films.

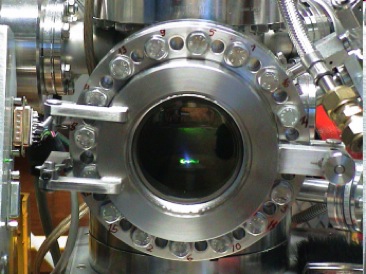

— Hybrid PLD/CVD reactor

Technological basis for thin film deposition is a UHV reactor chamber together with a pulsed Nd:YAG laser system for hybrid PLD/CVD processes. Therefore, solid (e.g. Si, Zn, Cu) and gaseous sources (O, N) can be used. The laser can be operated at 3 wavelengths, 1064 nm, 532 nm, and 266 nm, with a maximum 300 mJ pulse energy and 5 ns pulse duration. The CVD process is powered by a 100 W RF-generator at 13.56 MHz. PC-control of process parameters allows for simultaneous or sequential process protocols. The reactor system is designed for fast gas switching for attaining sharp interfaces. Separate vacuum chambers are available for either semiconductor-oxide material system deposition or ferroelectric film preparation.

— Low temperature equipment

An optical OXFORD bath cryostat is used for transport and for photoluminescence measurements in the temperature range between 80 K and 500 K. Both steady-state excitation by HeNe (633 nm), HeCd lasers (325 nm), and Xe light sources, together with various spectrometers, and pulsed laser excitation by Nd:YAG laser are possible.

— Microwave reflectometer

Contact-less measurement of carrier mobility and recombination lifetime is accessible with a microwave resonator system operated at 2.45 GHz.

Homepage: groups.ist.utl.pt/rschwarz/

Location

IST-Alameda, Pav. Física, floors 3 and 5

Access conditions

For all equipment, short-term access at any time for interested colleagues is welcome. Please, contact the scientific researchers in charge.

Semiconductor Materials and Energy Conversion – SMECL

Responsible and contacts

Ana Maria Amaral, ext. 3208

Description

The laboratory is equipped with a range of systems for thin film deposition, materials processing and characterization. The current areas of research include: amorphous silicon materials and devices, transparent and conductive oxides and their applications and crystalline silicon solar cells and electronic devices.

Materials deposition systems:

— Plasma Enhanced Chemical Vapor Deposition (PECVD), equipped with gases SiH4, PH3/SiH4(2,5%), B2H6/H2(2%), NH3, CH4, H2, Ar

— Plasma Enhanced Reactive Thermal Evaporation (PERTE)

— Diffusion furnace (up to 1000 °C) – Thermolab, custom-made

— Physical Vapor Deposition (PVD) by thermal evaporation

Materials processing systems:

— Reactive Ion Etcher (RIE) using SF6 and/or O2

— Photolithography and other chemical processing:

— Spinner Laurell WS-650MZ-23NPP

— UV exposure system (without micro-alignment);

— Thermal plate (up to 300 °C);

— Muffle (up to 300 °C);

— Ultra-pure water dispenser (Milli-Q – Direct-8)

— Ultra-sonic bath.

— Metalographic microscope (1000x max. magn.)

Characterization systems:

— Electrical characterization systems:

— Conductivity vs temperature (-20 to 80 ºC), in vacuum

— I(V) curves under dark conditions or under illumination (AM1.5), room temperature, up to 4 terminal devices

— I(V) curves under dark conditions or under illumination (AM1.5), vs temperature, up to 2 terminal devices

— C(V) measurements at room temperature

— Profilometer – Veeco Dektak3 (res. 20 nm)

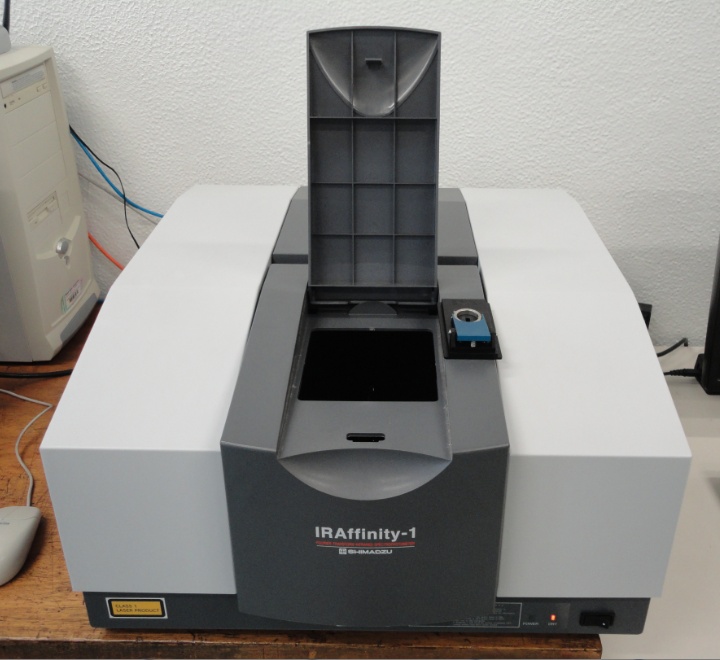

— Infra-red spectrophotometer (FTIR) – Shimadzu IRAffinity-1, wavenumber range: 7800 – 350 cm-1 (res. 0.5 cm-1)

— Four-point probe – Veeco FPP 5000

— UV-Vis-IR spectrophotometer – Shimadzu UV3100, 180 – 3100 nm (res. 1 nm).

Location

IST-Alameda, Complexo Interdisciplinar, 6th floor.

Access conditions

Within collaborative research work. Contact the scientific researcher in charge.

Hybrid PLD/CVD Reactor. UHV reactor with Zn target (white).

Liquid-nitrogen cryostat for VIS-UV optical transmission and photoluminescence.

Plasma-enhanced CVD system.

RIE system.

Profilometer.

IR spectrophotometer.

Laser Materials Processing Laboratory

This laboratory aggregates facilities on laser processing at IST and FCUL.

Responsible and contact persons

Rui Vilar (IST Lab.), ext. 1259

Olinda Maria Conde (FCUL Lab.)

Description

This laboratory is dedicated to the study of laser-materials interactions and the properties of materials processed by lasers at the macro/micro/nano-scales.

On-going research

(a) Additive laser manufacturing: laser-assisted deposition of single-crystalline Ni-superalloys and refractory materials by laser powder deposition; combinatorial design of metal-matrix ceramic reinforced composites and Ti alloys with improved biomechanical behaviour; metallic glass coatings for bioimplants;

(b) Femtosecond laser materials processing: laser structuring of ceramic and metallic materials for self-cleaning surfaces, biofilm growth inhibition and enhanced cell interaction in orthopedic and dental implants; laser nanostructuring of magnetic thin films of and study of the mechanism responsible for current-induced magnetization switching observed in these films; study of the ablation of biological hard-tissues, applied to minimally invasive dental and orthopedic surgery; study of the structural transformations induced in dielectric materials by intense ultrafast laser pulses;

(c) Pulsed laser deposition of oxide-based thin films and heterostructures and metallic multilayers for thermoelectric devices and magnetoelectronics.

Experimental installations located at IST and FCUL

– Laser micro/nanoprocessing system based on a Yb:KYW chirped-pulse-regenerative amplification laser, with 100-500 fs variable pulse duration and radiation wavelength of 1030 nm, and computer controlled XY stage (@IST)

– Laser powder (macro)-deposition system consisting of two 2kW cw Nd:YAG lasers, optical fibre beam delivery laser cladding head, pneumatic powder feeder, CNC 3D position system and controlled atmosphere chamber (@IST)

– Laser micro-cladding workstation consisting of a 200W fibre laser, piezoelectric powder feeder and computer controlled 4-axis positioning system, in controlled atmosphere chamber (@IST)

– Laser micromachining system based on an UV excimer laser operating at 248 nm (KrF) and 193 nm (ArF), in the nanosecond regime (@FCUL)

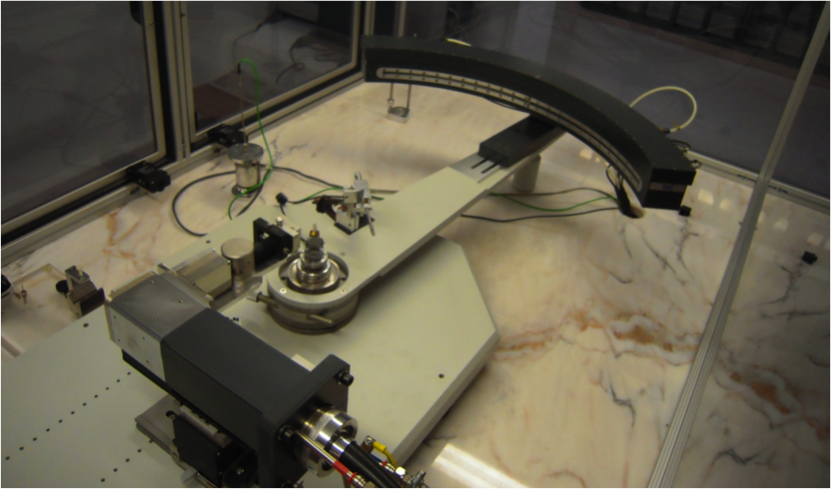

– Pulsed Laser Deposition system based on the excimer laser (previously described), and an ultra-high vacuum chamber equipped with a 6-target rotating holder (@FCUL)

– LCVD - Laser-assisted Chemical Vapor Deposition based on an high vacuum chamber and the above described excimer laser (@FCUL)

– MOKE - Magneto-Optical Kerr Effect magnetometry based on two wavelength laser diodes (blue and red) (@FCUL)

Location

IST Lab.: IST-Alameda campus, Pav. Matemática, floor -2, room 02.06 and Pav. Mecânica II, room 1.40

FCUL Lab.: FCUL, Dep. Física, Ed. C8, floor 4, room 8401

Access conditions

Within collaborative research work. Contact the respective scientific researcher in charge.

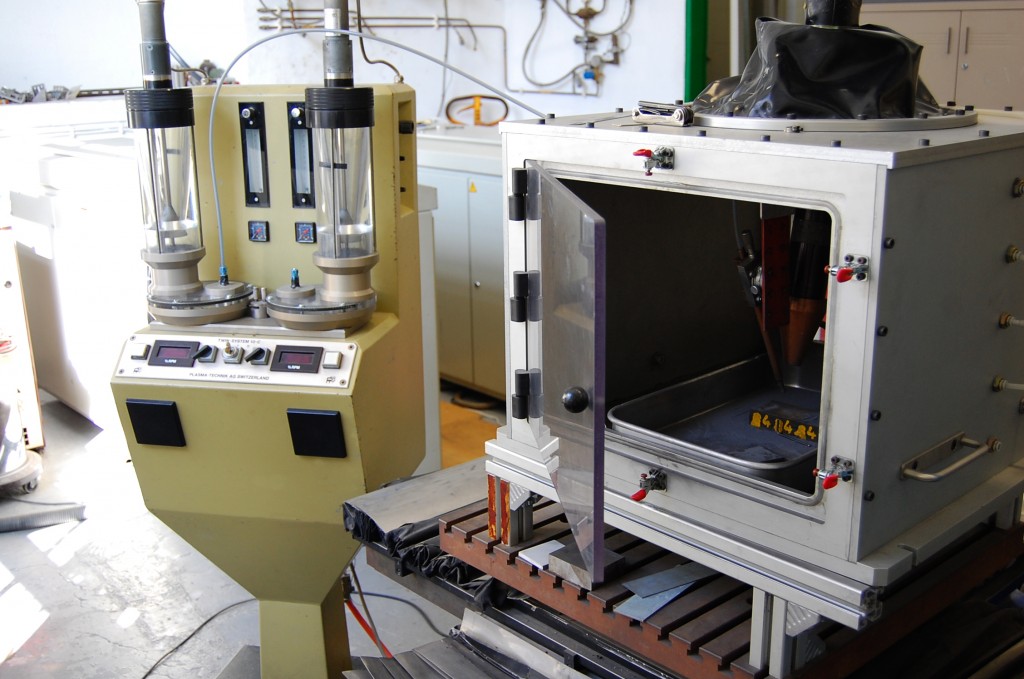

Laser powder (macro) deposition system @IST.

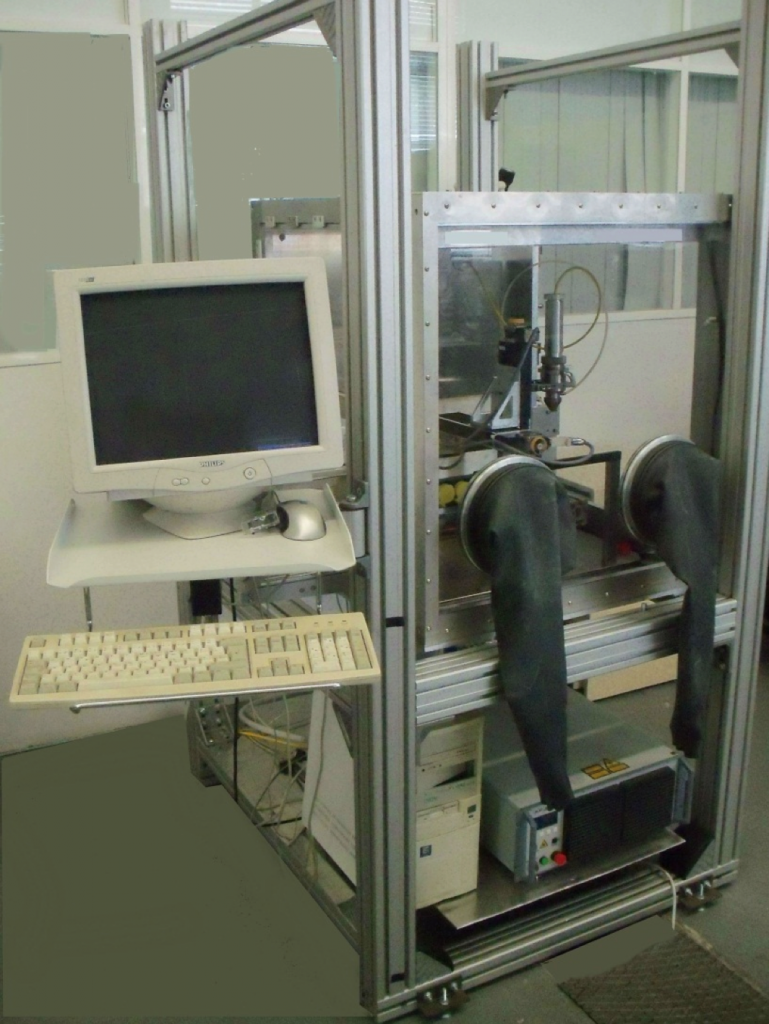

Laser micro-cladding workstation @IST.

Pulsed Laser Deposition system @FCUL.

Materials Preparation and Testing Laboratory

Tribology

Responsible

Rui Vilar

Contact Persons

Rui Vilar, ext. 1259

Maria Amélia Almeida, ext. 3176

Description

The laboratory is provided with methods for the mechanical characterization of surfaces at the micro and nanoscales.

Research activities

— Tribological and mechanical characterization of materials and coatings.

Main equipment

— Wazau TRM 500 Tribometer

This tribometer is used for friction and wear measurements under continuous or alternating sliding motion. It can be operated without or with lubrication, with solid or fluid lubricants in boundary or mixed friction conditions. Both materials and lubricants can be tested. The tribological pair may have pin on disc or sphere on disc configurations. The tests can be performed between RT and 850°C. Able to perform tests according to a wide range of European and American standards.

— Phoenix TE 66 Microtribometer

This microtribometer may be used to determine the abrasive and sliding wear coefficients of very small samples of coatings and materials in a ball on plate contact configuration. The machine may also be used as a crater-generating tool for coating thickness determination. Can perform tests according to BS EN 1071-6: 2007 standard.

— TA Instruments DSC

Multi-purpose calorimeter with microwatt sensitivity for continuous temperature scanning, step-scanning and isothermal measurements of phase transformations thermodynamics and kinetics data and determination of transformation temperatures.

— Shimadzu Microhardness tester

Vickers microhardness tester Shimadzu HMV2000, 2 Kg maximum load.

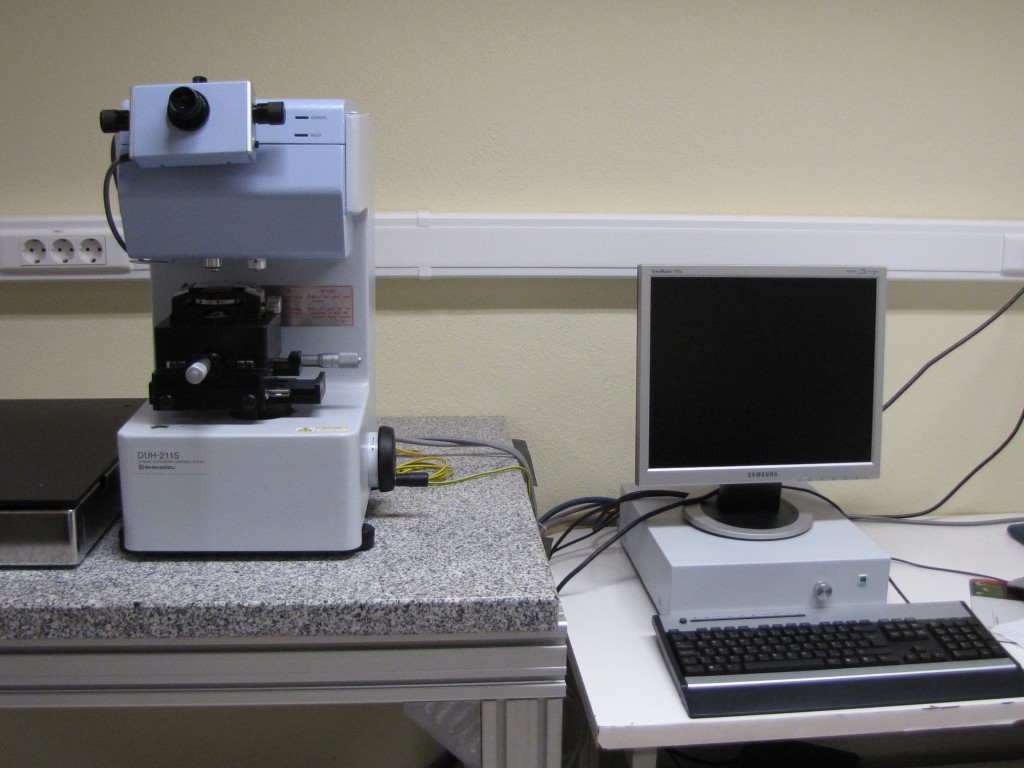

— Dynamic Ultramicrohardness Tester

Shimadzu DUH-211S depth-sensing ultramicroindentation tester. Dynamic indentation measurements, testing in localized regions and determination of elastic modulus and hardness of a wide range of materials. Load range: 0.1 – 1961 mN.

— Olympus PMG3 inverted metallographic microscope

Multi-purpose metallographic microscope equipped for bright field, polarized light and Nomarski interference contrast observation. Digital image acquisition and analysis.

— Nikon binocular microscope.

Location

IST-Alameda, Pav. Matemática, floor -2, room 02.05

Access conditions

Within collaborative research work. Please contact the scientific researchers in charge.

NanoStructured Materials Laboratory

Responsible and Contact person

Alberto Ferro, ext. 3989

Description

The laboratory supports the development and characterization of materials engineered so that multiple length scales are simultaneously produced. Particular focus is put on the production by the powder route of bulk nanostructured metal/ceramic or ceramic/ceramic composites with multiscale dispersions tailored for functional and structural performance under extreme conditions.

The laboratory also supports the production and characterization of colloidal suspensions, fine mineral based materials, and natural grown biostructures.

Main Equipment

— High-energy milling: planetary ball mill, Retsch PM 100 (2 units)

— High purity Argon Glove box: MBraun UNILAB Plus N/P Glove Box

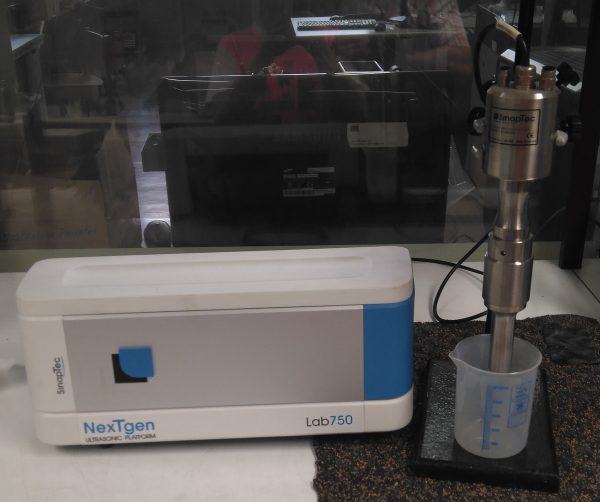

— High Power Ultrasonic Probe: Sinaptec Nextgen Lab750

— General equipment for colloidal processing

Location

IST-Alameda, Mecânica II, building, floor 0, LEM2 Laboratory.

Access conditions

To know more or have access to the list facilities please contact the laboratory responsible.

Wazau tribometer.

Phoenix TE 66 microtribometer.

Olympus PMG3 optical microscope.

Shimadzu DUH-211S dynamic ultramicrohardness tester.

MBraun UNILAB Plus N/P Glove Box.

Sinaptec Nextgen Lab750 Ultrasonic Probe.

Planetary ball mill, Retsch PM 100.

Laboratory of Membrane Processes

Responsible and contact person

Mónica Faria, ext. 3196

Description

The Laboratory supports the research activity of:

– synthesis and characterization of polymeric and mixed-matrix membranes

– analysis of flow structure and mass-transfer in feed channels with membranes, for the development of efficient membrane modules

– development of membrane hybrid processes and membrane reactors, using data from different types of membrane pilot plants

– synthesis and testing of electrochemical materials and processes.

Objectives

– Preparation, functionalization and characterization of polymeric membranes

– Analysis of flow and mass transfer at membrane/fluid interfaces

– Development of membrane hybrid processes and membrane reactors

Ongoing research

– Development of active/passive mixing methods for minimization of concentration polarization in membranes modules operating in laminar/creeping flow regimes

– Miniaturization of nanofiltration using micro fluidic devices

– Development of mixed-matrix celullose acetate membranes with silver nano particles

– Separation and purification of RG2 from wines using ultrafiltration

– Synthesis and purification of hydroxamic acids using ultrafiltration

– Analysis of the stability of proteins at freezing temperatures: Computational fluid dynamics simulation of the freezing process and measurement of protein diffusivity

– Nanofiltration and ultrafiltration of pulp and paper liquors for recovery of by-products

Main Equipment

— Membrane Bench Scale Equipment

Different set-ups are available to the membranes of ultrafiltration, nanofiltration, reverse osmosis, pervaporation, electrodialysis and gas permeation.

— Pilot plants for Process Evaluation

Water treatment, industrial wastewaters & biorefinery, food, etc.

Ultrafiltration, nanofiltration, reverse osmosis (1 m2 membrane area)

Pervaporation (2 m2 membrane area)

Electrodialisis (0.2 m2 membrane area)

— Electrokinetic Analyser

Determination of the zeta potential of membrane surfaces or powders through the measurement of the streaming potential induced by a given flow rate of electrolyte that passes tangentially to the membrane surface or across a bead of powder. Antoon Paar (Germany).

— Holographic Interferometer

Determination of concentration profiles in two-dimensional flows in slits with mass-transfer at the channel walls; determination of diffusion coefficients of liquid binary mixtures through the record of the unsteady-state concentration profiles in diffusion cells; measurements of binary diffusion coefficients in liquids solutions.

— Gas chromatograph

Analysis of disinfection by-products and pesticides in water for human consumption. The equipment has automatic injection (split/splitness), sample preconcentration and two detectors (Electron Capture Detector (ECD) and Photoionisation Detector (PID)).

— Micro PIV

Determination of the distribution of velocity vector field in micro channels through the technique of Particle Image Velocimetry (PIV). The system has a pulsed laser: model Solo II 15 Hz, from New Wave (Fremont CA, USA). Image acquisition system: Leica and Dantec.

— Laboratory equipment for chemical analysis

HPLC (High-Performance Liquid Chromatography), LC (Liquid Chromatography), GC (Gas Chromatography), Total Organic Carbon Analyser, Karl Fischer titration.

Location

IST - Campus Alameda, Torre Sul, floor 10, lab 10.6.6

Access conditions

Within collaborative research work. Contact the scientific researchers in charge.

Micro PIV with pulsed laser, model Solo II 15 Hz, from New Wave (Fremont CA, USA).

Electrokinetic analyser.

Gas chromatograph, model CP-3800 from VARIAN (Palo Alto, CA, USA).

Laboratory of Materials Electrochemistry

Responsible and contact person

Diogo Miguel dos Santos, ext. 1765

Description

The Laboratory supports the research activities in the synthesis and testing of materials for electrochemical energy conversion and storage.

Objectives

– Development of novel materials and technologies for application to environmentally friendly energy conversion and storage processes with industrial significance

– Development of materials for low temperature fuel cells, namely metal-based nanosized catalysts for borohydride electrooxidation, three dimensional cathodes for O2/H2O2 reduction, small-scale direct borohydride fuel cells, and alcohol-fuelled proton exchange membrane fuel cells

– Development of materials for water electrolysis, namely, functional cathodes for H2 production, and development of novel alkaline electrolysers

– Environmental oriented electrochemistry, namely development of disposable rechargeable Zn/MnO2 printable batteries on paper and their integration with printed paper based organic solar cells, mediated electrochemical oxidation of pollutants and carbon dioxide mitigation.

Ongoing research

– Functional materials for electrolytic hydrogen production (FCT project: PTDC/SEN-ENR/121265/2010)

– Low cost electrocatalysts for direct borohydride fuel cells (FCT Post-doctoral research grant, Diogo Santos)

– Novel cathode materials for direct borohydride fuel cells (FCT Post-doctoral research grant, Biljana Sljukic).

– Electrolytic hydrogen evolution in alkaline media using RTILs and Schiff bases (FCT Post-doctoral research grant, Luís Amaral)

Main Equipment

— Fuel cell testing facility

This fuel cell testing facility enables the monitoring of fuel cells. Equipment specifically designed to ensure the control and optimization of the key-parameters relative to the characterization of ion-exchange membranes and electrode/membrane interfaces.

— PAR 273 Potentiostat/galvanostat coupled with frequency analyser

The potentiostat available in our facilities enables using most conventional methods for electrochemical analysis using a three-electrode cell. Key-parameters related to novel electrocatalysts and technologies for fuel cells and electrolytic hydrogen production may be assessed with this equipment.

— Rotating ring-disc electrode controlled with bipotentiostat

This equipment is capable of controlling two working electrodes simultaneously. This capability enables the assessment of intermediate species in very fast electrochemical processes.

— Planetary Ball Mill

This equipment is a valuable tool for classical powder mixing and size reduction processes, and for mechanosynthesis.

Further information at http://meg.ist.utl.pt/

Location

IST-Alameda, Pavilhão de Minas, floor 4

Access conditions

Within collaborative research work. Contact the scientific researcher in charge.

PAR 273 potentiostat/galvanostat coupled with frequency analyser for EIS (Electrochemical Impedance Spectroscopy) studies.

Fuel cell testing facility.

Planetary ball mill.